Polyimide Heaters and Kapton Heaters

Polyimide Heaters and Kapton™ Heaters

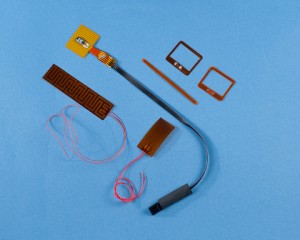

Northeast Flex Kapton heaters and polyimide heaters are manufactured from chemically etched resistive foils. The etched circuit design pattern is bonded between two layers of Kapton or polyimide insulating materials.

Northeast Flex can fabricate your Kapton heaters and polyimide heaters to a multitude of shapes, sizes and wattage. Both Kapton heaters and polyimide heaters are thin, light weight and durable with excellent dielectric strength. Kapton heaters and polyimide heaters are preferred for applications where space, weight, and low out gassing limitations exist.

Northeast Flex designs all Kapton heaters and polyimide heaters with uniformly distributed wattage, eliminating the need for edge loss compensation.NEF also provides a wide variety of control methods to manage and monitor your application. Kapton heaters and polyimide heaters can be supplied with thermistors, thermostats, thermal fuses, heat sinks and thermocouples. NEF will assemble the Kapton heaters and polyimide heaters to your application through the use of pressure sensitive adhesives and epoxies. Mechanical fasteners are also available in the form of clamps, ties, springs, snaps or belts.

Northeast Flex Kapton Heater and Polyimide Heater Specifications:

- Temperature range from: -200°C to +200°C

- Lightweight, thin and flexible

- Various lead terminations

- Excellent tensile strength and tear resistance

- Low out-gassing

- Resistant to most chemicals

- Resistant to many solvents and oils.

Northeast Flex Kapton Heater and Polyimide Heater applications:

- Aircraft and satellite dish

- Printing equipment industry

- Battery heaters

- Laboratory equipment

- Thermal developing

- Graphic imaging equipment

- Test equipment

- Medical equipment.